Porcelain Stoneware

Thanks to its excellent physical and mechanical properties, porcelain stoneware is ideal for outdoor use, since it is resistant to atmospheric corrosion and unaffected by UV exposure. Its qualities allow it to be water-and-oil repellent. Porcelain stoneware is obtained via the synthesizing process of ceramic clay, feldspar, kaolin and sand. These raw materials undergo grinding and atomization until a homogeneous particle size, suitable for pressing, is obtained. Firing takes place at 1150-1250°C for approx. 25-30 minutes in order to determine the ceramization of the mixture, ensuring the typical resistance to abrasion. The colors, veins and shadings of porcelain stoneware vary from piece to piece. Such difference indicates the plus value and the uniqueness of the product.

USE AND MAINTENANCE

The stoneware surfaces can be cleaned easily and do not require particular maintenance interventions. To clean the product we recommend use of a cloth dampened with water and mild detergent. Successively, rinse and dry with a dry cloth. Pay particular attention to the rinsing phase to prevent the accumulation of lime scale and dirt.

Colors

- 34 basaltina

- 35 statuario white

- 36 Emperador

- 51 Salt

- 53 Lead

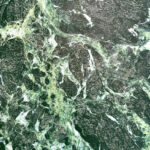

- 59 Alps Green